Magnetic separator

Home>Products center > Ore dressing machine > Details

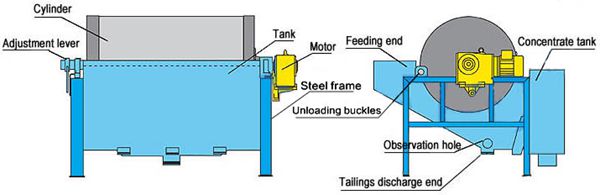

Magnetic separator

Processing ability: 1–220 t/h

Feeding size: 3–0 mm

Shell diameter: 600–1500 mm

Applied material: magnetite, pyrrhotite, calcined ore, ilmenite, etc

Introduction to magnetic separator

The dry magnetic separator or magnetic drum separator with its popularity is the most widely used equipment for separating different magnetic materials in industries like mining, timber, ceramics, chemicals and food etc. As for the mining industry, it is not only suitable for doing the wet or dry magnetic separation of manganese ore, magnetite, pyrrhotite, roasted ore, ilmenite, red limonite and other materials with particle size less than 50mm but also for doing deironing of coal , non-metal minerals and building materials.

The dry magnetic separator is divided into two categories and the permanent magnetic separator system usually uses high-quality ferrite materials or composite made with rare earth magnets. Its tube sheet used to own an average magnetic induction of 80-400mT. As the technology develops, the wet magnetic separator or China magnetic separator can be made into a roll shape and realize a magnetic field strength up to 1650mT which has been the biggest number measured.

Drum performance of magnetic separator

1. Roughing after the coarse and secondary crushing of the low-grade iron ore, excluding waste rock, etc., improving quality and reducing the burden of the next process

2. Applying to the grading of the uncompleted reductive raw ores from the hematite in the closed circuit roasting process and then returning to burn again.

3. For deironing of the petuntse in the ceramic industry to improve the quality of ceramic products.

4. For deironing of burning coal, foundry sand, refractory matters and other industries.

.jpg)

.jpg)

Parameter of magnetic separator;

| Model |

Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

-

How to Choose a Reliable Ball Mill Manufacturer?

[30/05/2017]

-

Research and Development is Valuable for Ball Mills

[28/11/2014]

-

Hammer Crusher Advances Fast in Information Age

[25/11/2014]